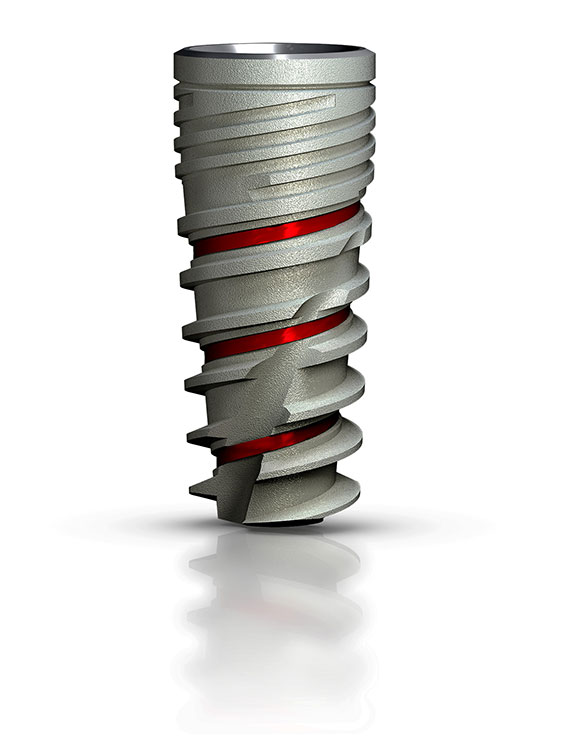

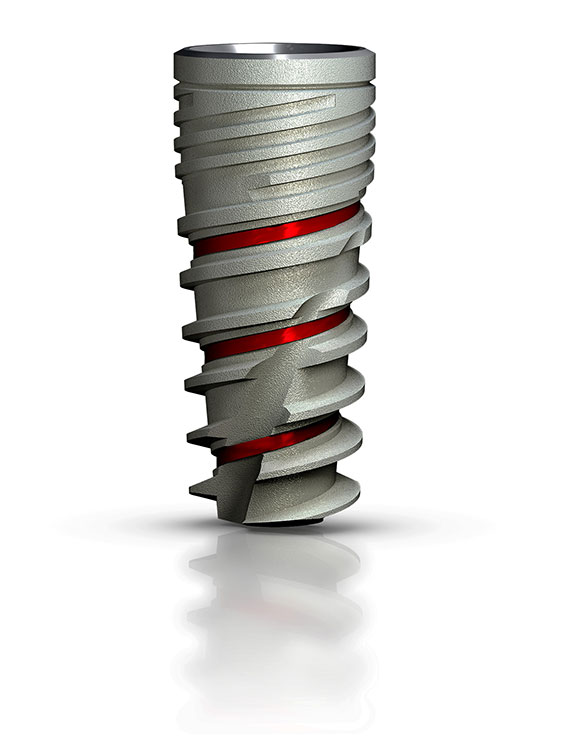

The Molecular Precision Implant System™ components are all designed in-house with the highest attention to safety, reliability and simplicity. Our multidisciplinary research & development team is equipped with the latest 3D CAD/CAM design capabilities.

All Ditron Dental implants and abutments share a standard internal hexagonal locking connection, so that the ideal combination may be assembled to address each specific case.

The Molecular Precision Implant System™ components are all designed in-house with the highest attention to safety, reliability and simplicity. Our multidisciplinary research & development team is equipped with the latest 3D CAD/CAM design capabilities.

All Ditron Dental implants and abutments share a standard internal hexagonal locking connection, so that the ideal combination may be assembled to address each specific case. This is the optimal basis for achieving a strong, functioning and esthetic final restoration.

Implant – abutment connection

We at Ditron Dental believe that the esthetics and long-term success of the final restoration are greatly influenced by the design of the implant-abutment connection. The well trusted design of the internal hexagon connection is further strengthened by our MolecuLock™ concept which incorporates very tight manufacturing tolerances in 3 critical parameters:

The Molecular Precision Implant System™ production process is specifically designed to tightly control these 3 key elements and in turn provide:

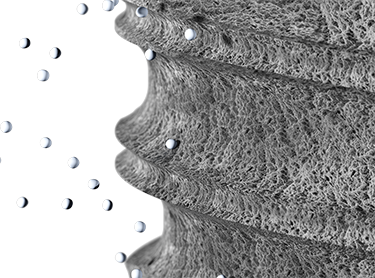

Minimal microgap

“Microgap” between the implant platform and the abutment is kept to an absolute minimum. This has the clinical benefit of reducing the possibility of bacterial contamination and improving the long term bone level stability.

Research & Development

We aim to provide the best dental implant solutions, and are continuously involved in science based research and development. We work with leading universities both in Israel and overseas. One leading example is our involvement in a novel gene based Peri-implantitis research:

“Genes Associated with Alveolar Bone Loss Around Implants and Teeth as a Result of Bacteria Induced Inflammation”.

For this research, Ditron Dental was challenged to create the smallest fully functional dental implant in the world.

This 50 micron diameter implant has allowed researchers to develop, for the first time, an innovative murine model for bacteria-induced alveolar-bone-loss around Titanium implants. Such a model can challenge the hypothesis that peri-implantitis and periodontitis are diverse phenotype and genotype conditions that share a common genetic background.

World’s smallest implant side by side with a 1 Euro coin