All Ditron Dental implants feature a blasted and thermally acid-etched endosseous surface.

To ensure repeatability, each and every implant is individually blasted with abrasive particles in an automated system which controls the speed, direction, pressure and size of the particles that collide with the implant. This ensures that each and every implant will undergo the same process and demonstrate the same excellent surface characteristics.

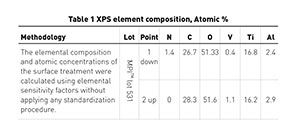

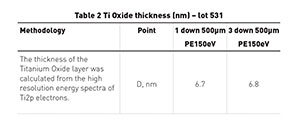

The excellent implant surface morphology is then created by a controlled thermal-acid-etching process. Finally, a high purity cleaning procedure is introduced to ensure that no foreign particles remain on the implant’s surface. The cleanliness level and purity of our implants are routinely checked by XPS measurements .

All Ditron Dental implants feature a blasted and thermally acid-etched endosseous surface. The micro and macro structure achieved by this process facilitates an accelerated osseointegration of the MPITM implants.

To ensure repeatability, each and every implant is individually blasted with abrasive particles in an automated system which controls the speed, direction, pressure and size of the particles that collide with the implant. This ensures that each and every implant will undergo the same process and demonstrate the same excellent surface characteristics.

The excellent implant surface morphology is then created by a controlled thermal-acid-etching process. Finally, a high purity cleaning procedure is introduced to ensure that no foreign particles remain on the implant’s surface. The cleanliness level and purity of our implants are routinely checked by XPS measurements .